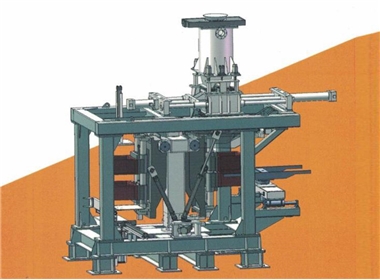

(Double standing sandblasting horizontal parting machine) imhando yemidziyo inoshandiswa muindasitiri yekukanda. Muchina wekuumba otomatiki unoshandiswa kugadzira simbi, simbi, aluminium uye zvimwe zvinhu zvesimbi.

Chigadzirwa chacho chine zvinhu zvinotevera:

1. Dual yakamira dhizaini: Midziyo ine nzvimbo mbiri dzekushandira, iyo inogona panguva imwe chete kuita kuzadza mold, compaction, jekiseni redhaka uye mamwe matanho ekugadzirisa kugadzirwa.

2. Sandblasting tekinoroji: Iyo midziyo inotora tekinoroji yejecha, iyo inogona kupfapfaidza dhaka muforoma kuti iite inodiwa yekukanda chimiro.

3. Horizontal parting: Iyo midziyo inotora yakachinjika yekuparadzanisa nzira kuti ipedze kudhirowa uye kutonhora maitiro ekukanda kuburikidza nekuvhura uye kuvhara kwe mold.

4. Kushanda otomatiki: Midziyo inoshongedzerwa neotomatiki control system, iyo inogona kuona otomatiki mashandiro ezvese maitiro ekugadzira, uye ine basa rekuongorora kukanganisa uye alarm.

Iyo kaviri yakamira sandblasting yakatwasuka muchina inoshandiswa zvakanyanya muindastiri yekukandira uye inogona kugadzira castings emhando dzakasiyana uye saizi, yakakodzera kune foundry uye kukanda zvinodiwa zvekugadzira zveese saizi.

Kaviri chiteshi jecha kupfura muchina une zvinotevera zvakanakira:

1. Kuvandudza kugadzirwa kwekugadzira: iyo mbiri-chiteshi dhizaini inoita kuti midziyo iite kuzadza mold uye kudurura, kuvhura mold uye kutora mashandiro panguva imwe chete, izvo zvinonyanya kunatsiridza kugadzirwa kwakanaka. Panguva imwechete yekudurura mune imwe chiteshi, imwe chiteshi inogona kugadzirira mold, iyo inoziva inoenderera kugadzirwa uye yakanyanya kushanda.

2. Chengetedza mutengo wevashandi: Nekuda kwekaviri chiteshi dhizaini, zvichienzaniswa neyechinyakare imwe chiteshi jecha kupfura muchina, kaviri chiteshi jecha kupfura muchina unoda kushoma kutora chikamu chebasa. Mumwe mushandisi anogona kudzora kushanda kwezviteshi zviviri panguva imwe chete, kuderedza mari yevashandi.

3. Kudzora kwakanyatso kudzora kwemhando yekukanda: Iyo kaviri chiteshi jecha jekiseni molding muchina yakashongedzerwa yepamusoro otomatiki control system, iyo inogona kunyatso kudzora tembiricha, kumanikidza, jecha jekiseni kumhanya uye mamwe ma paramita kuti ave nechokwadi chakagadzikana mhando yekukanda imwe neimwe. Uku kunyatsogona kutonga kunobatsira kudzikisa kukanganisa kwekukanda uye kuvandudza chiyero chekufanirwa kwechigadzirwa.

4. Shandura kune yakaoma kukanda kugadzirwa: Iyo mbiri-station jecha kupfura muchina wekuumba inoshandisa jecha core uye jecha mold kugadzira castings, iyo ine hunhu hwekuchinjika kwakasimba. Inogona kugadzira akasiyana maumbirwo akaomarara, chaiyo castings kusangana nezvinodiwa zvemaindasitiri akasiyana.

5. Kushanda kuri nyore uye kwakachengeteka: Dhizaini yekaviri chiteshi jecha rekupfura muchina inofunga nezve nyore uye kuchengetedzwa kweanoshanda. Iyo yekushandisa interface yemidziyo iri nyore uye yakajeka, iri nyore kubata uye kushanda, uye kuchengetedza zvishandiso zvinopihwa kuve nechokwadi chekuchengetedzwa kwemunhu anoshanda.

Kupfupisa, iyo kaviri-chiteshi jecha yekupfura muchina yave yakakosha midziyo muindasitiri yekukanda nehunyanzvi hwayo hwepamusoro, huchokwadi uye kugadzikana, uye inoshandiswa zvakanyanya mukugadzira kwakasiyana kwakaoma kukanda.

Nguva yekutumira: Oct-24-2023